Efficient management of the industrial electricity bill is a strategic tool for the competitiveness of any company in the industrial sector. Although many companies focus solely on the total amount to be paid, the true energy cost lies hidden in every line: energy charges, contracted power, regulated fees, grid tolls, and power factor adjustments.

Correctly interpreting these elements makes it possible to identify specific levers for savings that, when properly applied, can reduce costs by between 10% and 30% without decreasing production or compromising operational performance.

Below is a detailed guide —aligned with Spanish regulations— that explains which components make up the electricity bill, why understanding each section is crucial, how to audit your industrial bill step by step, and which strategies to apply to optimize it.

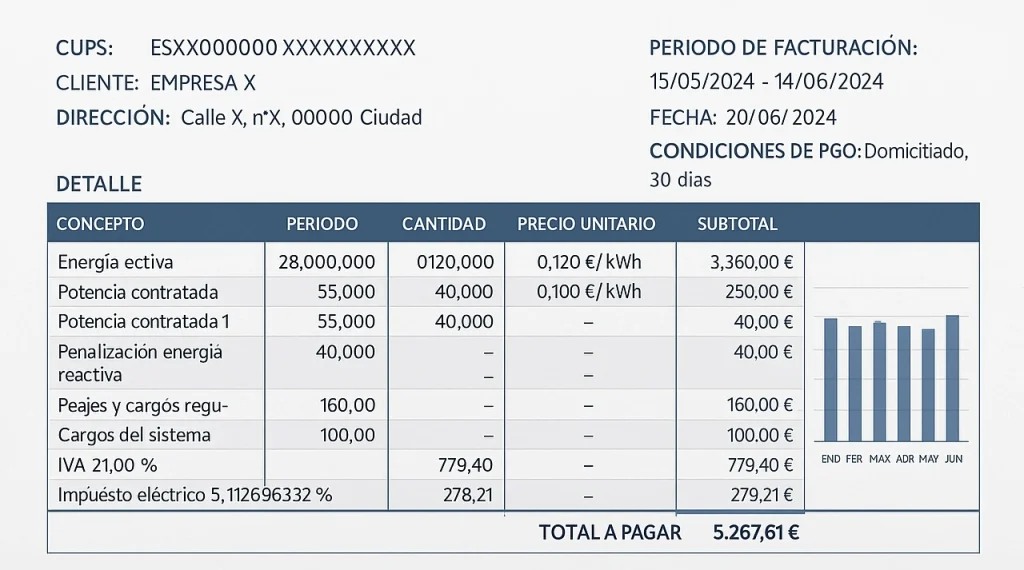

1. Anatomy of the Industrial Electricity Bill: What You’re Really Paying For

The first step in reducing costs is to understand which elements make up the bill and how each one affects the final cost of the industrial electricity supply.

1.1. Energy consumed (energy charge)

This section reflects the kilowatt-hours (kWh) actually consumed, multiplied by the agreed or regulated hourly price. In industrial facilities, the structure may include time-of-use (TOU) rates, meaning that the cost per kWh is higher during peak hours and lower during off-peak periods.

This segment usually represents between 35% and 60% of the total bill, depending on the consumption profile and operating schedule.

1.2. Contracted power / maximum demand

Instead of paying only for the energy consumed, many industrial tariffs include a charge for the peak power demand recorded during a given interval (usually 15 or 30 minutes). This charge is calculated in €/kW contracted or demanded and can represent a significant percentage of the total electricity bill.

When the contracted power is oversized, the company ends up paying for unused “capacity.” A technical review can adjust this value to achieve savings without operational risk.

1.3. Power factor penalties / reactive power

In facilities with many inductive devices (compressors, elevators, large motors), a low power factor (PF < < 0.90–0.95) is common due to reactive power consumption. In such cases, the utility company may apply additional charges or multiply the billed apparent power, which can increase the total cost by 2% to 8% if not corrected.

1.4. Access tolls, network charges, and transmission/distribution fees

These regulated costs cover the use of transmission and distribution networks, as well as associated energy losses. In Spain, they depend on the supply voltage (for example, rates 6.1TD or 6.2TD for high voltage) and are structured by time periods. They usually represent between 15% and 30% of the total electricity bill.

Choosing the right access tariff and voltage level can significantly influence this portion of the electricity bill.

1.5. System charges / regulatory adjustments

These include amounts established by the CNMC and MITECO to finance public policies, amortizations, renewable energy subsidies, territorial compensations, and other system costs. They represent between 5% and 15% of the total and vary depending on current regulations.

1.6. Taxes and fees

In Spain, the industrial electricity bill includes a 21% VAT and a 5% electricity tax. By optimizing the previous cost components, this tax burden is also proportionally reduced.

2. Why Analyzing the Industrial Electricity Bill Line by Line Is Crucial

- Prioritize the right measures: knowing which cost component dominates allows you to take action where it truly matters.

- Anticipate increases: network and power costs have risen by more than 40% over the last decade, while the energy component has increased by only 15%.

- Avoid hidden clauses: guaranteed minimum power levels, “ratchet” clauses, or standby tariffs for self-consumption without batteries can inflate annual costs.

- Increase technical and financial credibility: a clear breakdown makes it easier to justify savings projects to management, auditors, or investment funds.

3. How to Audit Your Industrial Electricity Bill Step by Step

Step 1: Collect the data

Download at least 12 months of hourly or 15-minute interval data from your electricity distributor’s online portal and save the corresponding invoices.

Step 2: Identify the demand peak

Determine the exact moment when the highest power demand occurs and analyze whether it is a recurring pattern or an isolated event.

Step 3: Verify the access tariff

Ensure that the tariff (for example, 6.1TD or 6.2TD) and the contracted power match the actual operating profile of your facility. Reviewing this can save thousands of euros per year.

Step 4: Reconstruct the bill

Multiply your kWh consumption by the applicable rates, add fixed charges and taxes, and compare the result with the actual invoice. If the difference is less than 5%, your model is accurate.

Step 5: Identify opportunities

Oversized or undersized contracted power.

High consumption during peak hours.

Penalties due to reactive power.

Outdated or inappropriate tariffs.

Step 6: Simulate scenarios

Assess the impact of changing the tariff, installing batteries, correcting the power factor, or shifting energy consumption. Prioritize actions based on return on investment and ease of implementation.

4. Four Key Strategies to Optimize the Industrial Electricity Bill

4.1. Batteries for Peak Shaving

Demand charges are calculated based on the highest monthly power peak. Batteries discharge energy during those critical moments, reducing both the peak and the associated cost.

A 500 kW / 2 MWh system can cut up to 300 kW in logistics facilities, generating savings of between €6,000 and €9,000 per month.

Ubora’s Energy-as-a-Service model allows this solution to be implemented with no upfront investment — the client only pays a percentage of the verified savings.

4.2. Tariff Optimization and Switching to Indexed or TOU Rates

Switching from a fixed tariff to an indexed industrial electricity tariff can reduce costs by 6% to 10%. TOU (Time-of-Use) rates charge less during nights or weekends, making them ideal for industries operating in shifts.

Simulating a full year before switching helps avoid billing surprises.

4.3. Power Factor Correction

A power factor below 0.9 results in penalties and additional costs. Installing automatic capacitor banks (≈ €20,000 for 0.5 MW) offers a payback of less than two years while improving efficiency and extending the lifespan of motors and electronic equipment.

4.4. Load Shifting with an Intelligent EMS System

Energy Management Systems (EMS) allow energy consumption to be automated based on tariffs, production schedules, and weather forecasts.

They can reduce the industrial electricity bill by 8% to 12% through dynamic demand management, such as pre-cooling, staggered charging, and scheduled equipment start-ups.

5. Regulatory Context and Evolution of the Industrial Electricity Bill in Spain

- Rates 6.1TD and higher: applicable to voltage levels from 1 kV to 30 kV, structured into six time periods (P1 to P6).

- Royal Decree 148/2021: regulates power and energy charges, as well as adjustments within the national electricity system.

- CNMC Circular 1/2025: tightens billing rules for excess power demand, encouraging the use of monitoring systems and battery storage solutions.

- Network costs: have increased up to 70% faster than the price of energy, making power and schedule optimization more profitable than ever.

6. Conclusion: How to Sustainably Reduce Your Industrial Electricity Bill

Analyzing an industrial electricity bill with technical precision is the first step toward controlling energy expenses. Each line —energy, power, charges, and taxes— reveals an opportunity for savings.

Applying a combination of strategies —such as battery storage, tariff optimization, power factor correction, and intelligent load management— can reduce total costs by 25% to 30% without affecting productivity or operational comfort.

Moreover, the growing shift toward self-consumption models with energy storage and PPA or EaaS contracts enables industries to maintain their energy competitiveness without making large upfront investments.

At Ubora, we help you reduce your industrial electricity bill

At Ubora, we thoroughly analyze every line of your industrial electricity bill, identify unnecessary costs, and design a tailored technical plan to minimize your energy expenses.

We handle the entire process —from consumption analysis and tariff simulation to the implementation of solutions such as batteries, EMS systems, or photovoltaic self-consumption— with financing that requires no upfront investment and guaranteed results.

Request a free analysis of your electricity bill and find out how much you can save.

If you want to learn more about this topic, we invite you to watch the following video on our channel.

For more content, visit our social media channels: